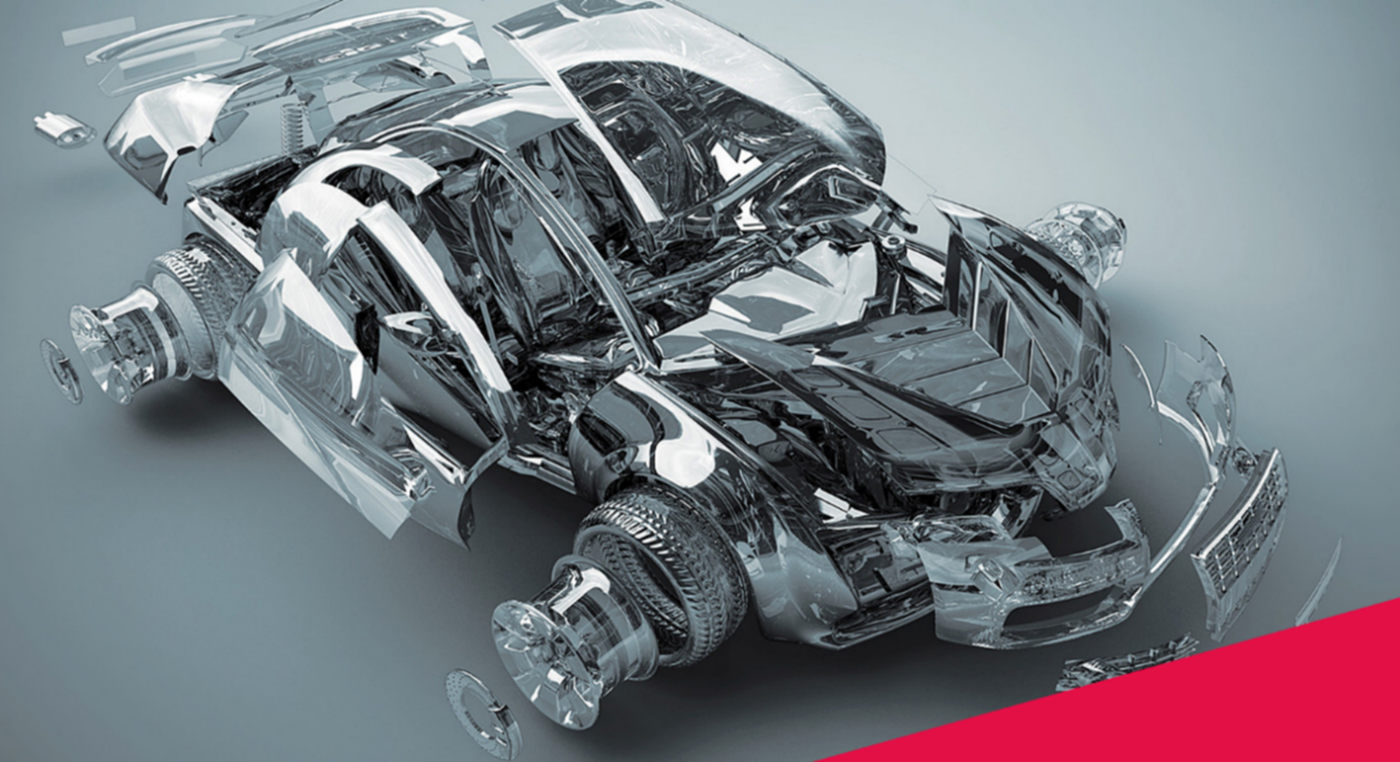

We focus on the development of vehicle structural parts, prioritizing safety, integration, cost efficiency, and lightweight design as our core values. With a profound understanding of each system design specification,we provide a full-process service from concept to mass production. By leveraging advanced structures, high-performance materials, and innovative processes, we enable optimal mechanical transmission and energy distribution, creating a strong and lightweight framework that ensures the safety of the vehicle body and battery. Over the years, we have provided high-quality solutions to numerous renowned automotive brands, gaining widespread recognition in the market.

The closure modules team specializes in structural optimization, function integration, and motion simulation, delving deeply into metal/plastic components, accessory motion mechanisms and sealing systems. With our extensive experience in hood, trunk lid and door designs (rotary type, split type, etc.), as well as innovative designs like concealed external water stripping, electric suction door locks, etc., we consolidate technical resources to provide our customers with high-quality and customized design solutions.

We have a comprehensive exterior design guideline and provide full-process engineering solutions encompassing target definition, material selection, joint strategy, functional verification, prototype support, and launch build assistance. We are also actively advancing the development and application of novel exterior materials and processes, optimizing aerodynamics and aeroacoustics, adapting to new mobility concepts and autonomous driving, and enhancing the new scene experience of smart exterior design - we are the engineering experts for exterior components.

The professional lighting team is dedicated to delivering comprehensive engineering services to OEMs and automotive lamp suppliers. Our services encompass styling analysis of lighting systems, selection and layout of functional lighting optical solutions, intelligent human-computer interaction design, engineering development, prototype production and validation, rigorous testing and design verification to ensure quality. We also provide customized services tailored to our customer’s needs, including visual verification and optical performance assessment.

Our key priority is to provide our customers with outstanding and customized lightweight solutions, ensuring a full-process service from concept to mass production. Leveraging our extensive technical experience, we assist customers in clarifying their lightweight objectives and conducting a thorough evaluation of cost, weight, and feasibility. This not only shortens the development cycle but also leads to highly efficient designs. Through the application of advanced materials and innovative technologies, we swiftly bring our customers' ideas to life, enabling them to excel in the competitive market.

We specialize in the design and development of different modules for hard interiors such as instrument panels, console, and door panels. With a deep understanding of the design of each module, we optimize the structure, applying new materials and processes, integrate EE and safety systems to create a safe, comfortable, and intelligent driving and riding space, For many years, we have provided high-quality solutions for numerous well-known automotive brands, winning widespread market recognition

We focus on the development of complete seat systems and components, with safety, comfort, functionality, good appearance, and lightweight as our core. With a deep understanding of the design of each module of the seat and complete seat guideline book, we can provide a full process engineering design service from concept analysis, layout, design development, data production and release, verification, supplier management, 3C certification, series production, including heating, ventilation, massage, table board, leg rest, armrest and other functions, which increases comfort and improves customer satisfaction.

We have a complete design guide for soft interior parts, which can provide a full process engineering solution from target definition to series production (including sound absorption, acoustic performance, material selection, connection strategy and functional verification). We also actively expand the development and application of new materials and processes for soft interior, optimize air acoustics, adapt to new mobile concepts and autonomous driving, and enhance the new scene experience of soft interior.